Integration of automation systems

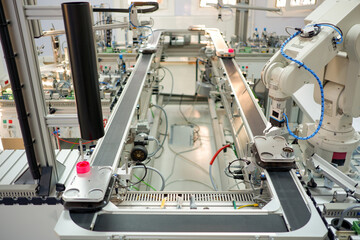

The integration of automation systems mainly involves linking machines, equipment, tools, as well as technological processes so that they are able to work as efficiently as possible, and at the same time autonomously. Performing systems integration results in speeding up work while relieving the burden on employees. As a result, the company is able to function much more efficiently. As part of the services we provide, our experienced engineers are able to carry out effective automation system integrations that are highly customized to the individual company’s needs.

- Automation system integrations based on manufacturers such as SIEMENS, Allen Bradley, Rockwell Automation, SAIA, among others

- Selection of equipment and system components

- Activating systems to work with functioning automated systems

- System maintenance care

- Training on implemented technologies

Integration of automation systems is a way to achieve greater efficiency in the first place. It results from minimizing the number of tasks that are performed manually in favor of those that can be performed without additional handling. By integrating systems, work organization can be significantly improved, which in turn is associated with reduced costs.

Integration of systems is an excellent solution for growth-minded companies that care about increasing the efficiency of their operations. Our customers can count on comprehensive advice and support at all stages of the work, starting with familiarization with the specifics of the company and its needs, through development of the strategy and implementation of the plan, to testing of the introduced solutions and warranty and post-warranty service.

We offer integrated IT tools to optimize information flow, quality control, data collection and analysis, and effective production management. We develop integrations based on well-known manufacturers such as SIEMENS, Allen Bradley, Rockwell Automation, SAIA and many others.